Glossy Material

The OctaneRender® Glossy material is used to simulate any shiny object, such as plastics, glossy paint, etc. It is possible to simulate metals with the Glossy material; however, the Metal material is preferable to render physically accurate metals. For physically accurate reflections, you can set the BRDF function to either Beckmann, GGX or Ward. These models simulate real surface properties such as the physical precision of the specular lobes, the fresnel effect, the law of conservation of energy, and anisotropy. The original Octane BRDF is not physically accurate, but it is useful when rules need to be broken.

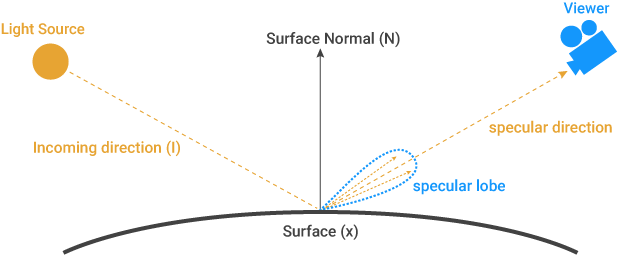

In reflection law, when the photon is hit by a surface, the reflection angle of light is equal to the angle of incidence. Photons do not spread around the surface as it is in diffuse reflections. The energy of the irradiance from any point (I) to the point (x) on a smooth surface is reflected from this point in a special direction called the specular direction (see below diagram).

The radiance energy that comes to the surface usually reflects the light by creating a light lobe around the specular direction (Also called "specular lobe"). The shape of this lobe is determined by the difference between the exit angle of the light and the specular direction. These Specular Lobes can grow and shrink depending on the roughness value on the surface.

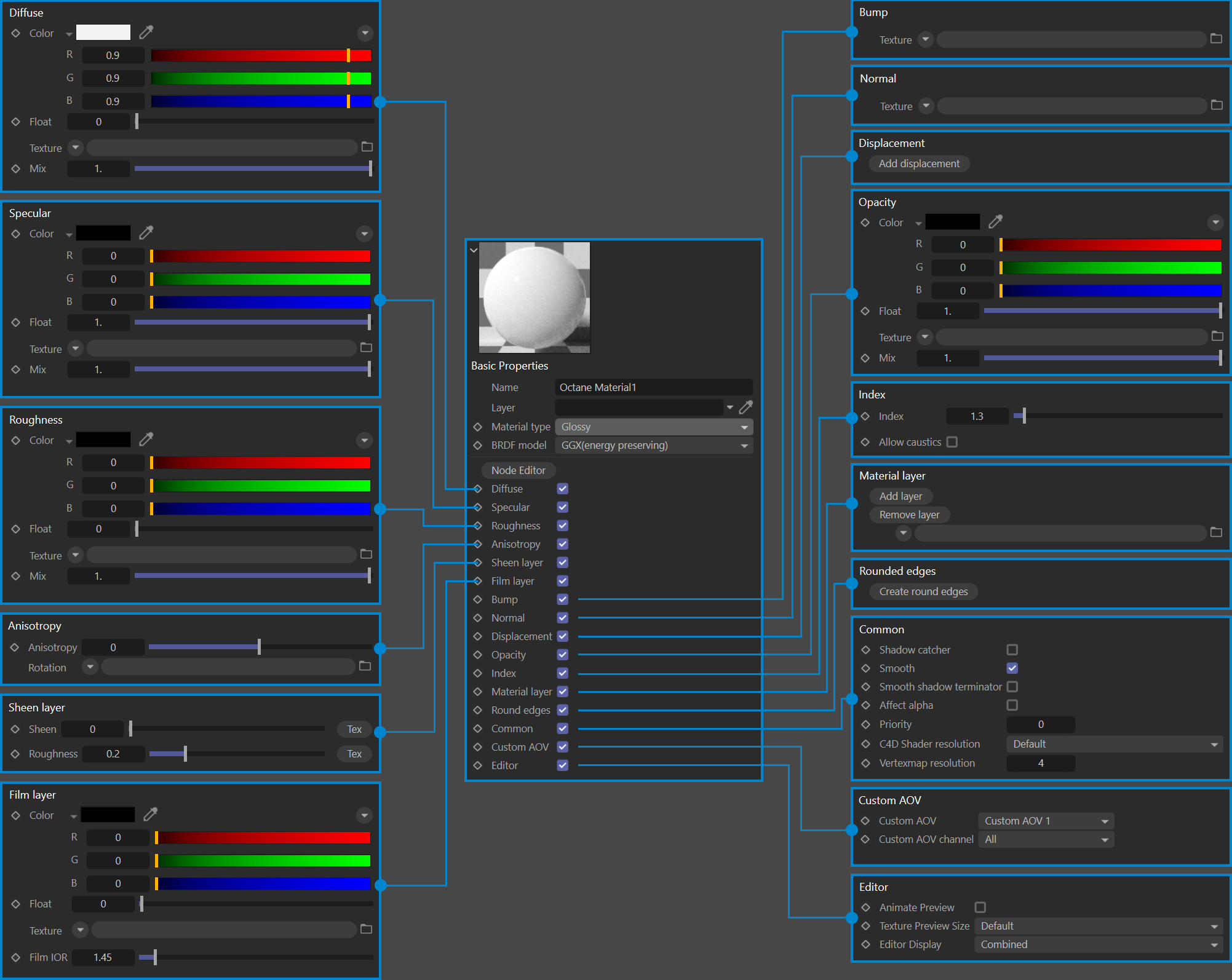

The illustration below represents the Glossy Material user interface. Relevant options are discussed as follows:

|

|

glossy Material

|

Diffuse

The Diffuse parameter gives the material its color, also referred to as “Base Color” or “Albedo." Diffuse color can be set using a value or by using a procedural or image-based texture.

Specular

This parameter adjusts the amount of reflection on the surface. The Float value is disabled when using RGB color. In the image below, there are renders of various Specular values with a Roughness value of 0.0.

|

|

GLOSSY material — SPECULAR

|

Roughness

The roughness parameter is used to simulate the smoothness of a surface. Higher values are used for rougher surfaces. While 0.0 is the default roughness value, it is not realistic to use this value when simulating real life surfaces of any kind, as nothing is perfectly smooth. Small values of roughness (0.001, for example) for super smooth surfaces will produce a more natural result.

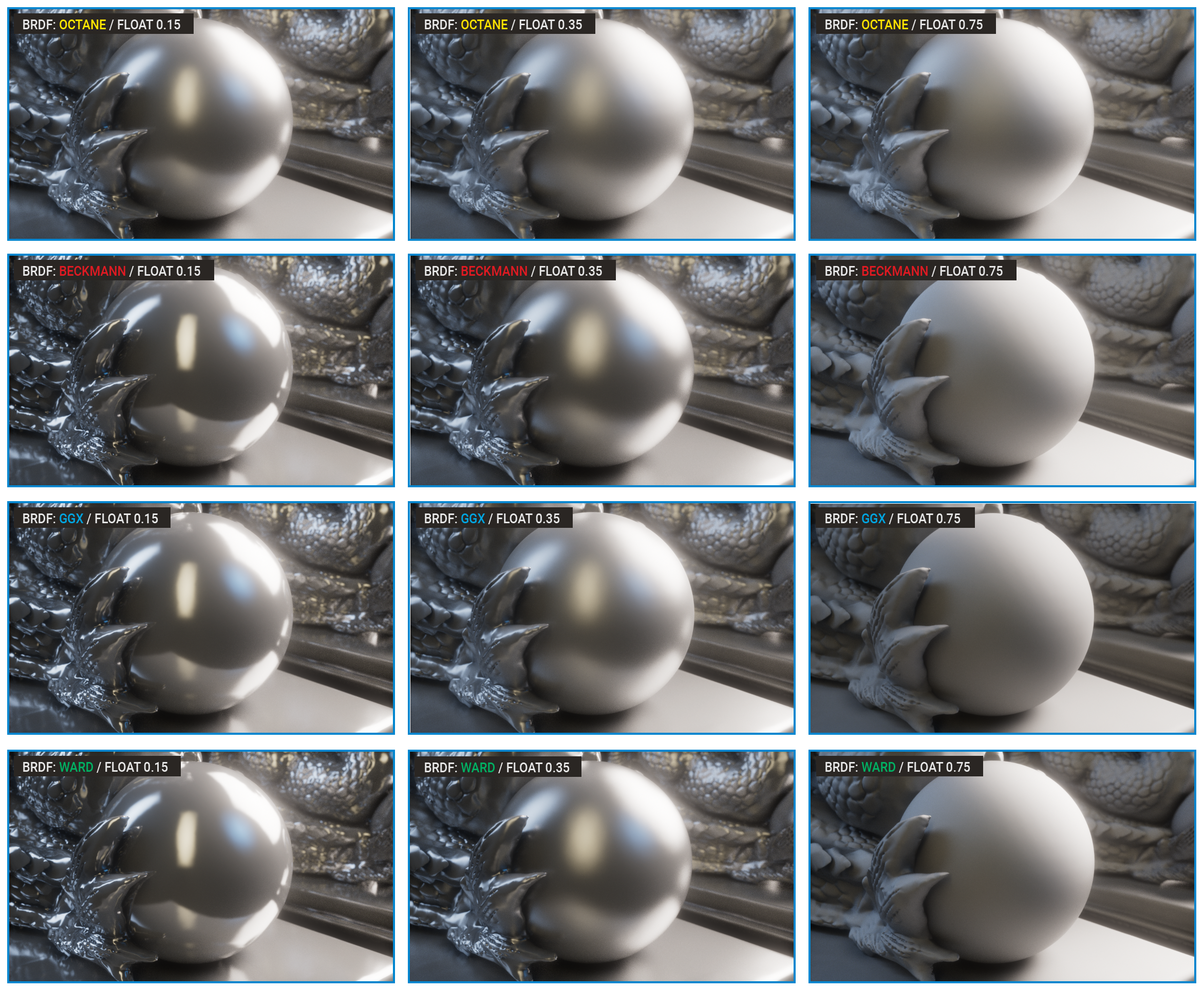

Specular surfaces usually reflect light by creating a light lobe around the specular reflection direction. The shape of this lobe is determined by the difference between the exit angle of the light and the specular direction. This resulting lobe creates blurring effect due to its roughness. The larger the specular lobes, the more blur and the surface looks darker. In computer terminology, this is called "reflection blur". This value behaves in accordance with the law of conservation of energy in BRDFs that provide physical results. In other words, the incoming light is scattered in more directions during reflection, resulting in energy loss. This is the explanation that the lobe goes towards darkness as the size increases. Even at extreme values, the surface almost starts to show diffuse properties, as illustrated below. Note that only the GGX, Ward or Beckmann BRDF types follow this rule — the original Octane BRDF does not.

|

|

glossy material — roughness

|

Anisotropy

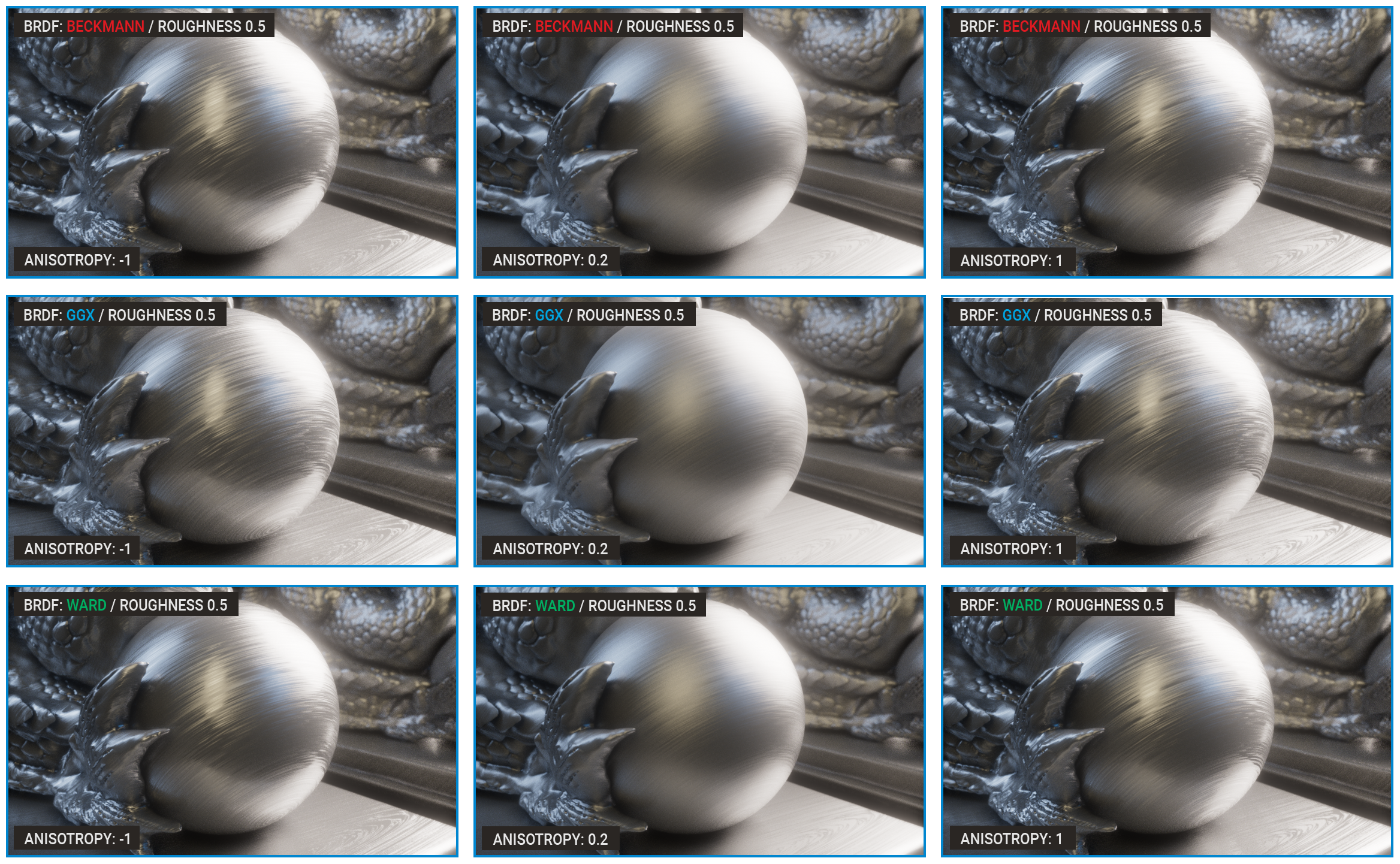

Anisotropy refers to reflections that can be non-circular or biased in a particular direction. Examples of anisotropic surfaces include polished metal, human hair, fur and wood. The anisotropy feature is available for the GGX, Ward and Beckmann BRDF models only, and a roughness value greater than 0.0 is required. There are two values that control the final result:

Anisotropy: Determines the amount of anisotropy applied to the surface. This value can be either negative or positive.

Rotation: This value allows for the anisotropy to be defined by a grayscale image texture or procedural (including OSL textures).

Proper surface normals and UV coordinates have a significant impact on the result with Anisotropy. The following image shows the anisotropic properties of different BRDF models. In this image the roughness value is fixed, and a grayscale image texture is used for rotation.

|

|

glossy material — anisotropy

|

Sheen

This option is mainly used for simulating clothes and velvet/satin like materials. It works by increasing the reflectance for grazing angle with varying roughness. Less roughness means a sharper peak of sheen reflection around the grazing angle, higher roughness means a less sharp peak and a more spread-out sheen reflection across the fabric surface.

Sheen requires use of either GGX, GGX (Energy Preserving) Ward or Beckmann BRDF models only.

To use Sheen, create a Glossy material and enter the values you see in the image below to get started. Adjust the Roughness parameter to increase or decrease the Sheen effect.

|

|

GLOSSY material — SHEEN

|

Film Width & Film Index

Film width simulates the look of a thin film of material on the surface. This will create a prismatic effect such as the colors that appear on the surface of an oil slick, or a soap bubble. Larger values increase the strength of the effect. The Film Index controls the Index of Refraction of the thin film, use this option to adjust the colors visible in the film. This parameter will use either RGB color/Float Value and image/procedural texture values. In the image below, a grayscale image texture is used for Film width. The Film Index is 2.2.

|

|

GLOSSY material — FILM WIDTH & FILM INDEX

|

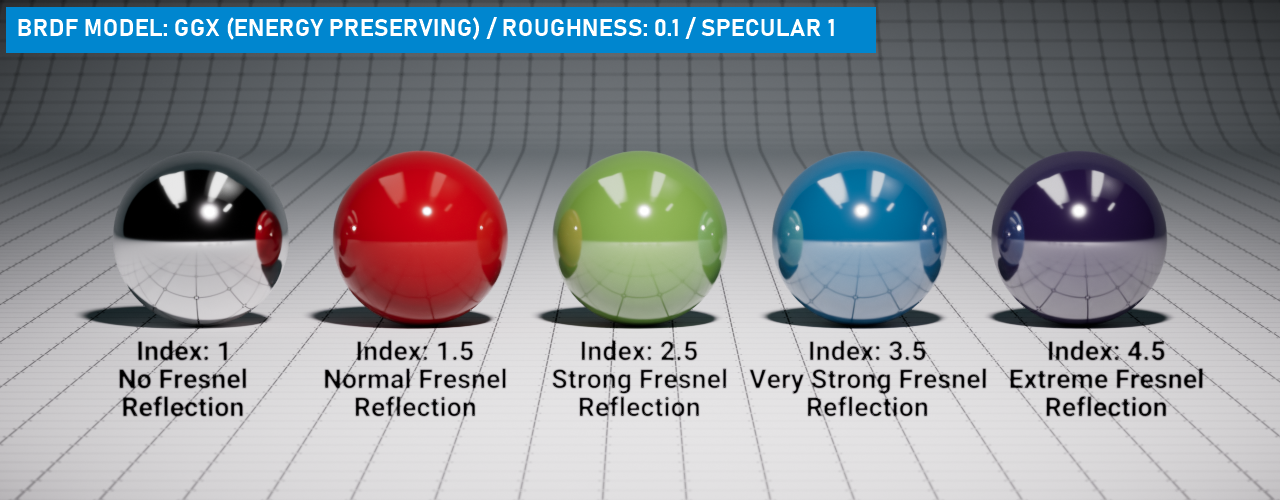

Index (Index of Refraction)

This parameter, also known as IOR or Refractive Index, determines the reflection strength of the surface according to the fresnel reflection law. Fresnel dictates the amount of reflectance depends on the observer's angle and surface IOR values. In reality, every surface has a refractive index. A great resource for IOR values is https://refractiveindex.info/ — "Selected data for 3D artist" section on the main drop-down menu is a good place to start. The values that presented at RefractiveIndex are "n" and "k" values, which are called "complex index of refraction" components. As the Glossy Material does not have a slot to specify n and k values separately, choose the n for the preferred IOR. If more precision is required, both the Metal and Universal materials have slots for the n and k values.

The Allow Caustics toggle enables caustics when the Photon Tracing kernel is active (discussed here).

|

|

GLOSSY material — INDEX COMPARISON

|